1. ZERO WASTE

A few years ago we invested heavily in recycling equipment to convert the residual flow released from the punching of all our productions into raw material for injection molding. We produce, among other things, with our injection molding machines consumption coins, shopping cart coins and accessories. This allows us to use around 30% of our residual flow for new products, for example ECO Consumption Tokens and Recycle Tokens. We have been able to make full use of the remaining 70% since 2019 by including it again in the production of new films for our die-cutting products. (tags and labels). So Zero Waste!

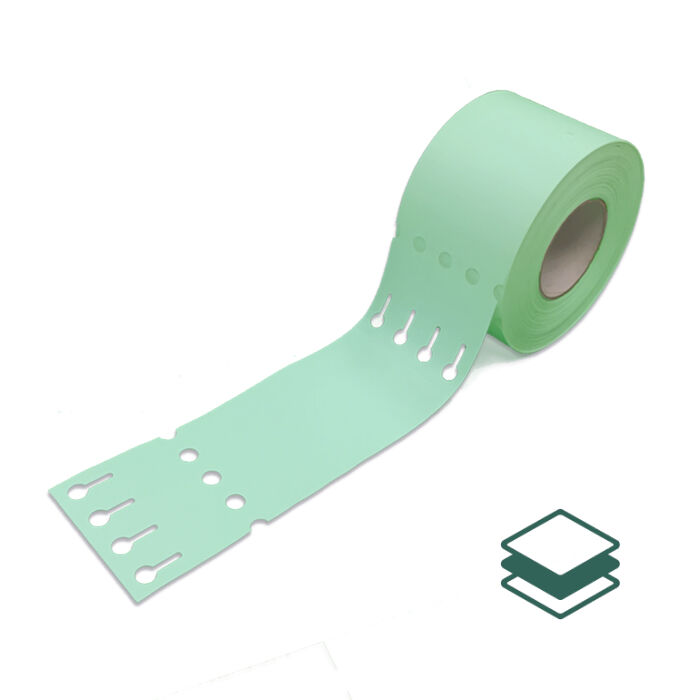

2. RECYCLATE USE:

How do we use the 70%? Green core!

VanDerEng, in collaboration with its suppliers, has developed a material called: Greencore.

Greencore is a material consisting of a combination of recycled (85%) and virgin HDPE, so it can meet climate targets and the needs of customers who want to achieve optimal printing results with Thermal Transfer on our tags and labels.

Products made from this have significantly less impact on the environment. We naturally guarantee that they have the same functional properties as materials made from so-called 'virgin' raw materials. This way you as a user can also contribute to the environment.

3. BIOMATERIALS

VanDerEng BV, together with Wageningen University, is developing a material made from renewable and edible raw materials. The aim is to develop a raw material from which we can initially injection mold products with sufficient dimensional stability, moisture resistance and stiffness. This material will without industrial composting fully absorbed into nature after 6 months under the influence of light, moisture and oxygen! Of course, the product may be added to the organic waste after use.

4. FOOTPRINT REDUCTION

By taking the above steps, but also by finding local suppliers, utilizing our residual flow and producing from recycled materials, VanDerEng BV has reduced its footprint with 18%. We aim to achieve an even higher percentage of this by calling on all our customers to join us in becoming more sustainable.

VanDerEng BV has been active for years to give our production a sustainable character. We work on the environment at four levels, not only in terms of personnel, but certainly also in dealing with the use of plastics.